Virtual Server, Virtual Desktop

Server, Workstation, PC, Peripherals

Windows, Unix, Oracle, SQL

Netapp, Buffalo

Network System Design & Construction

Fundamentals Course, Advance Course, Custmized Course

3DEXPERIENCE Entrance

Order Custom-made Training for specific applications. CADmeister, FTI, XVL, CADdoctor etc..

Annual Maintenance Support

CAD/CAM/CAE/PLM Consultation & Implementation

CAD/CAM/CAE/PLM System Operation Support

IT System Administration Support

APIS IQ is one of the most advanced softwares for both FMEA, DRBFM and Functional Safety on the market.

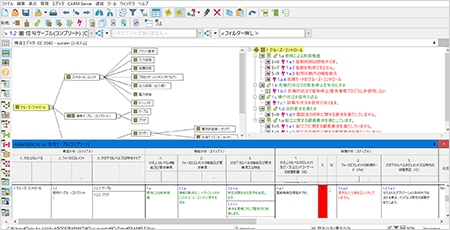

APIS IQ is capable of systematic failure analysis that is not possible with conventional FMEA. FMEA sheet, FTA, DRBFM, Pareto analysis chart, risk matrix, control plan, process flow diagram, etc. The net and these outputs are synchronized with each other.

The most unique feature of APIS IQ is the net. There are three types of nets: structure, function, and failure.By breaking down from structure to function to failure, systematic failure analysis is possible. In addition, by analyzing on the net, the causal relationship of structure → function → failure can be visualized.

The function net visualizes the causal relationship between the product function and the function of each structure (component), and is useful for failure analysis of products with complex functions. In the failure net, the causal relationships between failures extracted from each function are visualized, and they become the relationships of effects, failure modes, and causes. FMEA advocated by VDA is an analysis method for such a network.

After completing the analysis on the net, you can output to the FMEA sheet. The causal relationship of the failure clarified by the failure net is directly mapped to the effect, failure mode, and cause of the FMEA sheet.

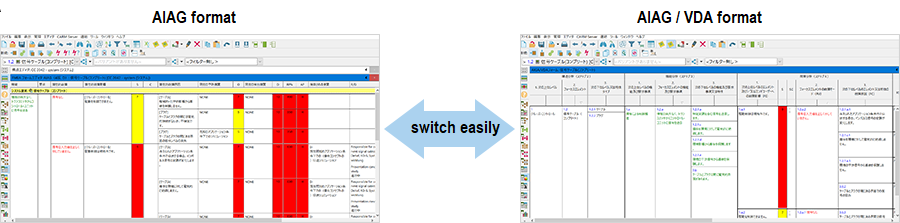

FMEA sheets are available in VDA format and AIAG/VDA format, and can be switched freely.

Also, the AP required for AIAG/VDA is automatically calculated. The net and FMEA sheet are synchronized with each other.

It supports 11 languages including Japanese, English, German, and Chinese. By entering the translation of the wording, it can be reflected not only in the operation menu but also in all the contents created in the file.

It is also possible to display both the main language and the reference language.

*Not a translation function.

Function nets and failure nets are effective for safety analysis of systems with complex functions such as those covered by ISO26262.

Specific functions include functional safety parameters, ASIL settings, SPFM/PMHF/LFM target value settings and automatic calculations, DC and FIT settings, and FMEDA functions.

In addition, as a safety mechanism analysis, error detection, error response, and operating conditions can be set to failure nets.

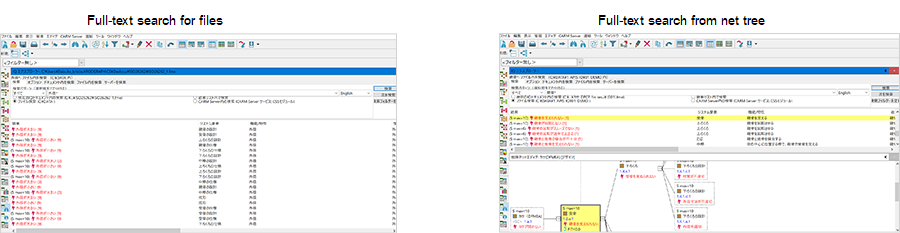

APIS IQ files are databases, and full-text search is possible for each object (by function or failure).

Since the information can be checked on the net or in the FMEA sheet, it is easy to judge whether the information can be reused.

By simply copying and pasting the net, all data such as the FMEA sheet attached to the net can be easily reused.

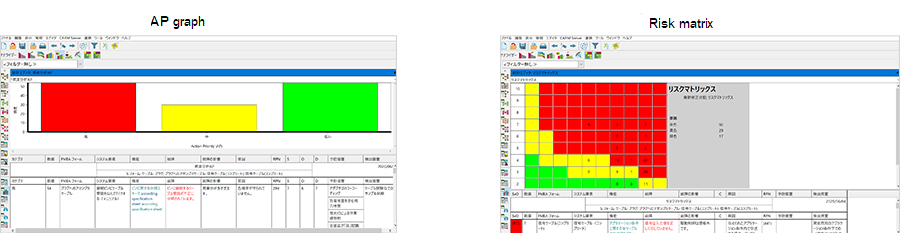

The statistics function can output various statistical graphs. For example, a Pareto analysis chart or a risk matrix.

By selecting a graph, you can check detailed information and jump to the net or FMEA sheet, so you can easily check what the high-risk failures that need to be addressed are.

You can also graph the new metric AP.

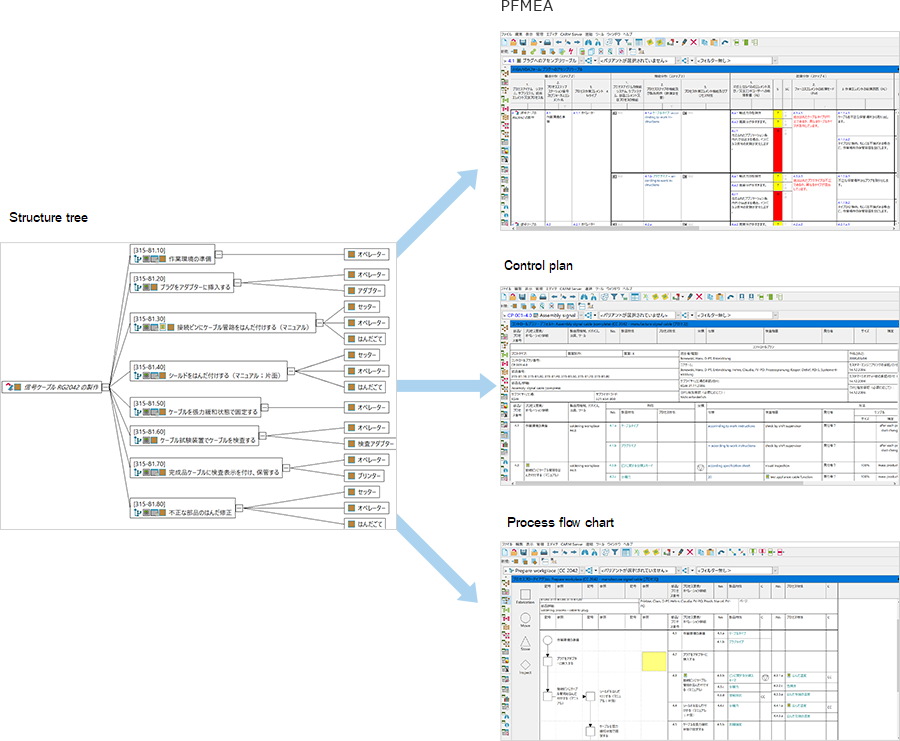

The tree created by PFMEA describes the process sequence, product characteristics, and process characteristics.

Based on this information, process flow diagrams and control plans can be generated, and PFMEA, process flow diagrams and control plans can be synchronized with each other.

If the specification of product characteristics is changed, the change will be reflected in all reports of PFMEA, process flow diagram, and control plan.

Introduced in order to apply international standard FMEA with the transition from TS to IATF16949.

In particular, it is effective in maintaining consistency in the flow of DFMEA -> process flow -> PFMEA -> control plan.

It was introduced to achieve more efficient and accurate management than Excel.

DFMEA → PFMEA → Control plan cooperation has become smoother in database management, and we expect to improve work efficiency.

In accordance with the AIAG/VDA handbook released in 2019, you can automatically output to the AIAG/VDA form from the APIS structure tree, function net, and failure net.

Since it can also be output to the conventional AIAG form, it is possible to handle both with one data, making business more efficient as well as customer service.

Feel free to contact us for products and solutions.

Contact