Customer

We own many different CADs at our company.

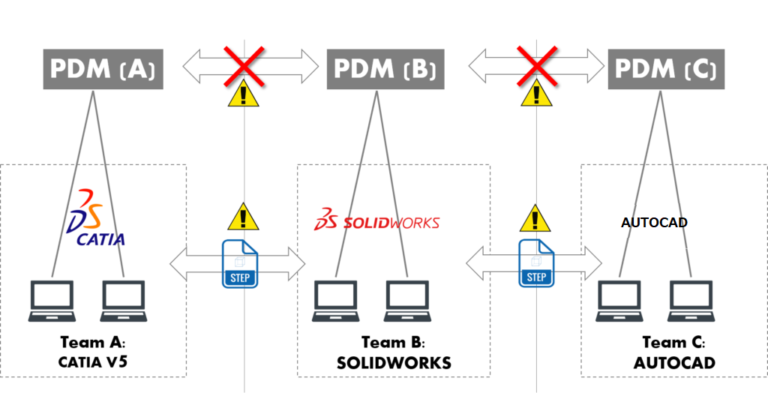

And we manage them with the different PDMs.

Different CADs with Different PDMs brings us a lot of time consuming works with high-maintenance and high cost…

NSS

We understand that. We usually need to use different CADs depending on specific works, or OEMs/Suppliers you work with.

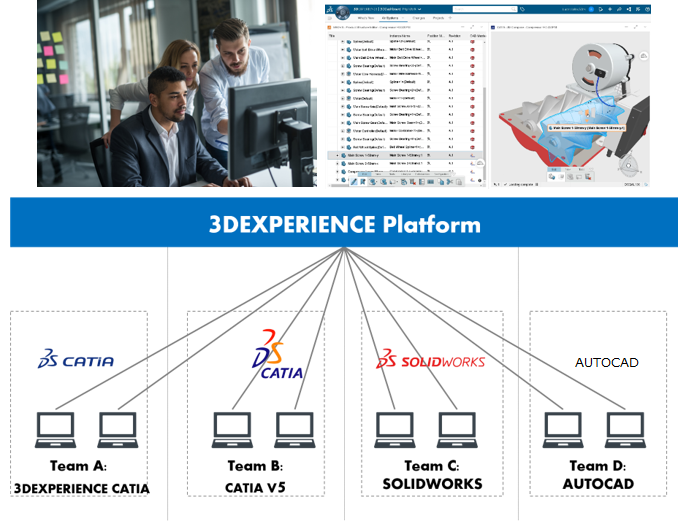

How about working with multi-CAD designs within One Single Environment of 3DEXPERIENCE platform.

Multi CAD management with different PDMs? or with a single platform, 3DEXPERIENCE Platform?

Let’s see how different they are.

Manage with different PDMs (Current);

- Managing different CAD with different PDM. -> High cost, High maintenance

- Managing standard parts with each CAD -> Slow down product development.

- Data exchange with intermediate file such as STEP. -> No access to the latest update in real-time.

Multi CAD management (3DEXPERIENCE Platform);

- A single platform (Single Source of Truth): -> Reduce cost and time for management.

- Manage standard parts on a single platform: -> Accelerate product development.

- Directly access the latest update seamlessly on a single platform.

- Final product reviews on a single platform without CAD file conversion.