NSS

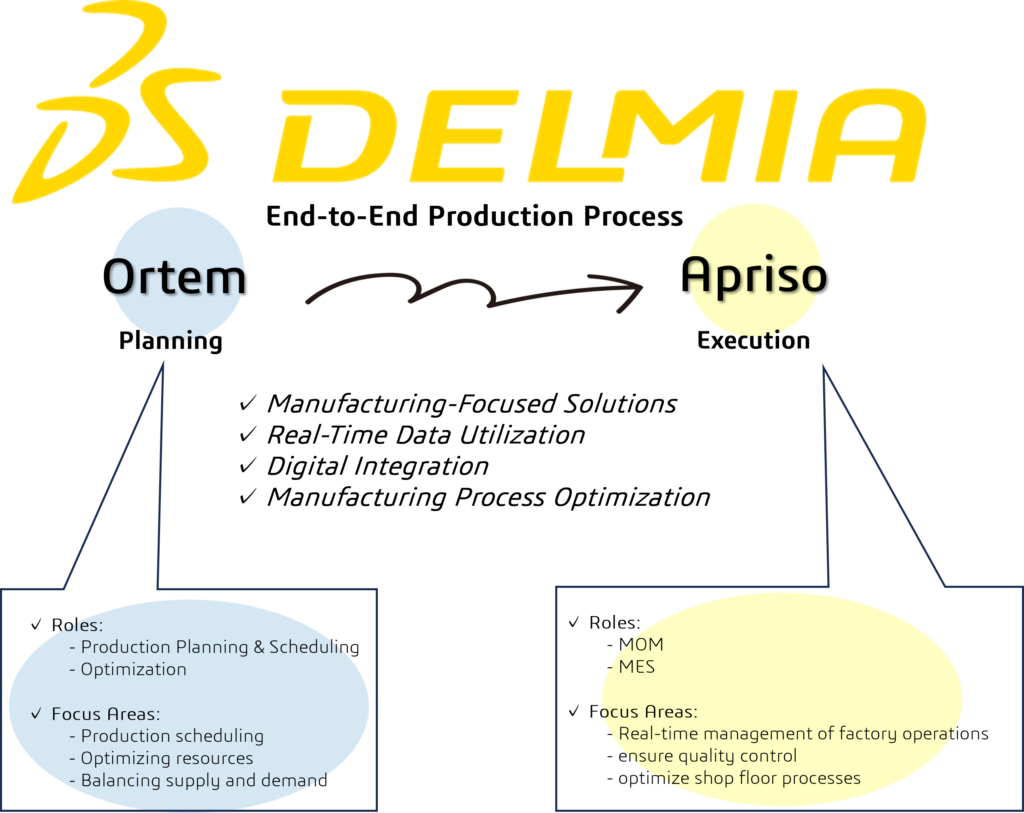

Both “DELMIA Apriso” and “DELMIA ORTEM“ belong to Dassault Systèmes’ DELMIA product suite, aiming to achieve efficient manufacturing processes, but they differ in purpose and functionality.

- “DELMIA Apriso”: Focuses on real-time Manufacturing Operations Management (MOM) and Manufacturing Execution System (MES)

- “DELMIA ORTEM”: Specializes in optimizing production planning and scheduling

Customer

Could you explain the differences between the two in more detail?

NSS

DELMIA Apriso(Manufacturing Execution System: MES, Manufacturing Operations Management: MOM)

Main Purpose:

- Real-time management and execution of factory operations

- Visualization and traceability of manufacturing operations

– Key Features:

✔ MES (Manufacturing Execution System) functionalities (manufacturing operations management)

✔ Real-time production monitoring (overall factory performance management)

✔ Enhanced quality control and traceability (tracking of products and materials)

✔ Integration of multiple sites (supporting global manufacturing networks)

Use Cases:

- Factory management for smart manufacturing

- Quality control and compliance in industries such as pharmaceuticals, aerospace, and automotive

NSS

DELMIA ORTEM(Advanced Production Scheduling)

Main Purpose:

- Optimization of production planning and scheduling

- Real-time adjustment of manufacturing processes

– Key Features:

✔ Advanced Production Scheduling (APS: Advanced Planning & Scheduling)

✔ Optimal resource utilization (allocation of workforce, equipment, and materials)

✔ Real-time production planning adjustments (adapting to demand fluctuations and equipment failures)

✔ Identification and optimization of bottlenecks

Use Cases:

- Optimization of production planning in automotive, aerospace, and high-tech industries

- Real-time scheduling considering demand fluctuations and production constraints

Customer

I see, I understand the differences now.

| DELMIA Apriso | DELMIA ORTEM | |

| Purpose | Management of manufacturing operations(MES) | Optimization of production scheduling |

| Key Features | Manufacturing management, quality monitoring, traceability | Production planning, resource optimization, schedule management |

| Real-time Capability | Real-time monitoring at the factory floor level | Mainly at the planning level (short- and mid-term) |

| Users | Manufacturing operators, quality management teams | Production planners, factory managers |

| Scope | Factory MES and operational management | Scheduling of the entire manufacturing process |